1、高强螺栓的紧固须分为两次进行,为初拧,初拧紧固到螺栓标准轴力(即预拉力)的60%-80%,初拧的扭矩值不得小于终拧扭矩值的30%,第二次紧固为终拧,为使螺栓群中所有螺栓均匀受力,初拧、终拧都应严格按照紧固顺序操作,按“米”字型对称操作。

1. The tightening of high-strength bolts must be carried out in two stages. The first stage is the initial tightening, which should be tightened to 60% -80% of the standard axial force (i.e. pre tension) of the bolt. The initial tightening torque value should not be less than 30% of the final tightening torque value. The second stage is the final tightening. In order to ensure that all bolts in the bolt group are evenly stressed, both the initial and final tightening should be strictly operated in the tightening sequence, symmetrically in the "meter" shape.

2、初拧完毕的螺栓,应做好标记以供确认,为防止漏拧,当天安装的螺栓,当天应终拧完毕,不得在雨天安装螺栓,且摩擦面应处于干燥状态,终拧扭矩须按设定值要求进行。

2. The bolts that have been initially tightened should be marked for confirmation. To prevent missing tightening, bolts installed on the same day should be fully tightened on the same day. It is not allowed to install bolts on rainy days, and the friction surface should be in a dry state. The final tightening torque should be according to the set value requirements.

3、严格按照电动扭矩扳手操作规程进行操作,每次用完扳手后一定要归零,以免造成弹簧的金属疲劳,应定期校准标定扳手的扭矩值,其偏差不大于5%。

3. Strictly follow the operating procedures for electric torque wrenches. After each use, the wrench must be reset to zero to avoid metal fatigue of the spring. The torque value of the calibrated wrench should be calibrated regularly, with a deviation of no more than 5%.

4、假设紧固螺栓的力矩或预紧力很准,但由于外力,温度变化、振动等因素,一段时间后的预紧力仍会变化,仍须校核。

4. Assuming that the torque or pre tightening force for tightening bolts is accurate, but due to external forces, temperature changes, vibrations, and other factors, the pre tightening force will still change after a period of time and still needs to be verified.

所以说,拧螺丝也不是你想象中那么简单的。

So, tightening screws is not as simple as you imagine.

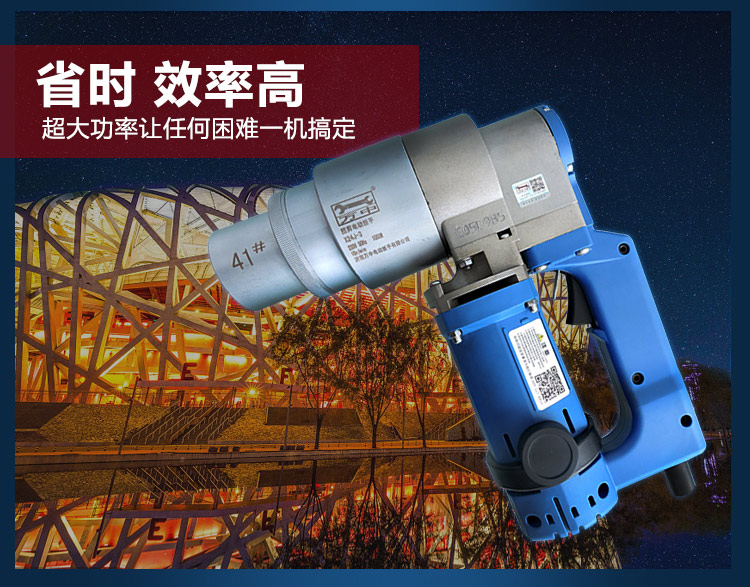

高强度螺栓连接作为钢桥连接的重要方式,因其效率高、性能好、可靠的优点,在工程领域得到了广泛的应用,施工用的扭矩扳手,其误差应控制在±5%,因此,紧固大六角螺栓需采用的紧固工具。螺栓因受力大小不达标从而导致质量事故得不偿失。山东汉普机械电动扳手专用于紧固有扭力要求的大六角高强螺栓,工作时需提前设定好要求的扭矩值,机器达到设定好的扭矩之后自动停止。

High strength bolt connection, as an important way of connecting steel bridges, has been widely used in the engineering field due to its advantages of high efficiency, good performance, safety and reliability. The error of torque wrenches used in construction should be controlled within ± 5%. Therefore, professional tightening tools are required to tighten large hexagonal bolts. The quality accident caused by substandard force on bolts is not worth the loss. Shandong Hanpu Mechanical Electric Wrench is specially designed to tighten large hexagonal high-strength bolts with torque requirements. When working, the required torque value needs to be set in advance, and the machine will automatically stop after reaching the set torque.

感谢您的阅读,此文的文章来源:扭剪螺栓专用扳手更多的内容和问题请点击: 我们会继续努力的为您提供服务,感谢您的支持!

Thank you for reading. The source of this article is the torque shear bolt wrench. For more information and questions, please click: We will continue to work hard to provide you with services. Thank you for your support!