由于电动扭剪扳手是高频应用工具,为了提高测量精度,有必要定期校准和检验工具,并配置满足使用要求的电动扭剪扳手设备。 目前,电动扭剪扳手主要由检定仪对电动扭剪扳手进行校准,检定仪需要定期检验。 由于校准环境是试验室环境,因此与现场操作环境有很大的不同。 为了确保校准管理的有效性,有必要参考实际使用现场进行管理,并且要求偏差不受使用场合的影响。 使用前要注意检验电动扭剪扳手的准确性,并根据使用频率调整校准和维护的频率。 通常每年不少于一次,利用维护管理手段保证电动扭剪扳手的准确性。

Due to the fact that electric torque wrench is a high-frequency application tool, in order to improve measurement accuracy, it is necessary to regularly calibrate and inspect the tool, and equip it with electric torque wrench equipment that meets usage requirements. At present, electric shear wrenches are mainly calibrated by calibration instruments, which require regular inspection. Due to the fact that the calibration environment is a laboratory environment, it is significantly different from the on-site operating environment. In order to ensure the effectiveness of calibration management, it is necessary to refer to the actual usage site for management and require that deviations are not affected by the usage situation. Before use, pay attention to checking the accuracy of the electric torque wrench and adjust the calibration and maintenance frequency according to the frequency of use. Usually, at least once a year, maintenance and management measures are used to ensure the accuracy of the electric torsion wrench.

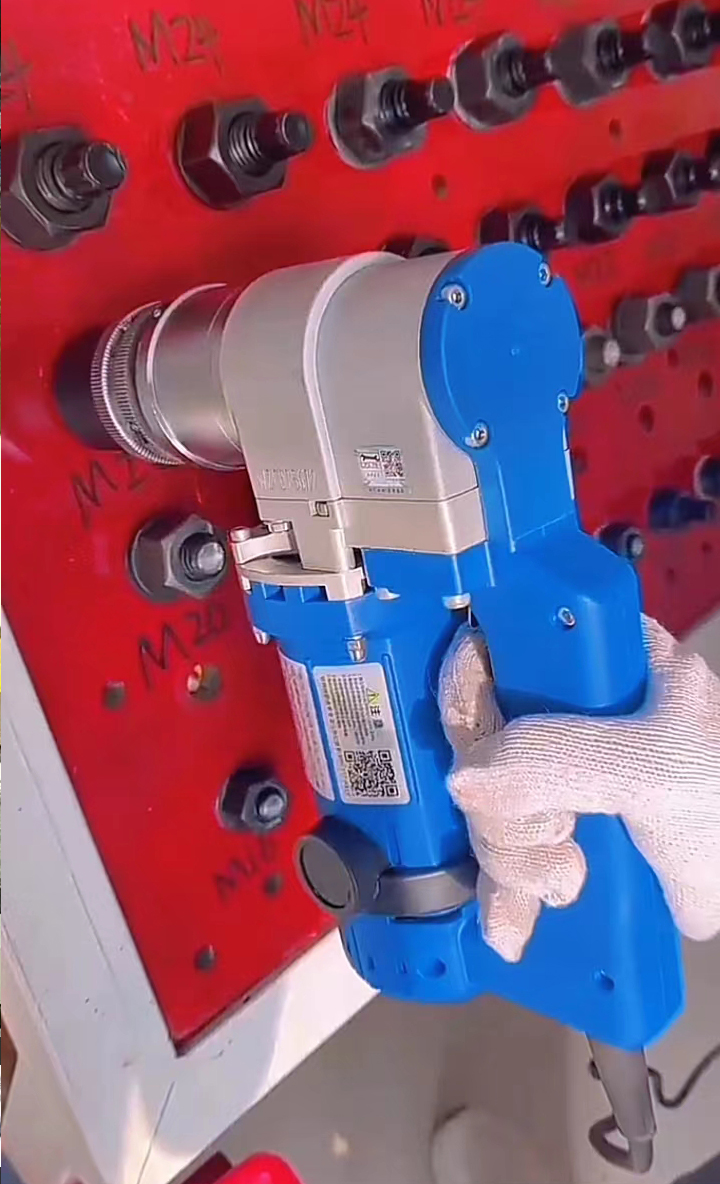

电动扭剪扳手的准确使用方法:

Accurate usage method of electric torsion wrench:

电动扭剪扳手主要用于安装紧固件,例如螺栓,螺钉和螺母。 通过扭矩控制,确保了螺纹的拧紧,并且不会因扭矩过大而损坏螺纹。 因此,有必要使用电动扭剪扳手进行扭矩值固定操作,在施加过程当中需要预先设置固定扭矩值。 当达到设定值时,电动扭剪扳手将发出提醒信息,可以感觉到手部振动或听到“喀哒”声,即扭矩已完成。 当扭矩值达到固定位置时,无需继续施加力。 请勿使用冲击力,停止施加力后,各个零件复位。 施加扭矩时,将手握在电动扭剪扳手手柄的中间刻度线上,并仅在电动扭剪扳手指示的方向上施加力,同时施力方向应在±15°以内(垂直方向和水平方向)。

Electric torque wrench is mainly used for installing fasteners, such as bolts, screws, and nuts. By torque control, the tightening of the threads is ensured and the threads are not damaged due to excessive torque. Therefore, it is necessary to use an electric torque wrench to fix the torque value, and the fixed torque value needs to be pre-set during the application process. When the set value is reached, the electric torque wrench will emit a reminder message, indicating that the torque has been completed by feeling hand vibration or hearing a "click" sound. When the torque value reaches a fixed position, there is no need to continue applying force. Do not use impact force. After stopping the application of force, all parts should be reset. When applying torque, hold your hand on the middle scale line of the electric torque wrench handle and apply force only in the direction indicated by the electric torque wrench. The direction of application should be within ± 15 ° (vertical and horizontal).

根据紧固件的强度和扭矩用以使用合适量程的扳手,并且不允许高于扳手的适用范围。扳手在使用前需要调零,无荷载时注意对扭矩扳手指针的检验,看指针是否在零标度值上,如果不是则需要对其进行调整。 为确保读数准确,在使用过程当中需要用一只手握住扳手的手柄,使扭矩扳手和拉力保持直角,并稳定地施加力。 当指针指向扭矩值时,禁止用力过大,否则会出现偏差值。 测量结束后,旋转旋钮将指针返回到零位,以便进行下一个应用。 作为测量工具,必须注意保护电动扭剪扳手。禁止进行扔掷、震动以及敲击等。

Use a wrench with an appropriate range based on the strength and torque of the fastener, and do not allow it to exceed the applicable range of the wrench. The wrench needs to be zeroed before use. When there is no load, pay attention to checking the torque wrench pointer to see if it is on the zero scale value. If it is not, it needs to be adjusted. To ensure accurate readings, it is necessary to hold the handle of the wrench with one hand during use, keeping the torque wrench and tension at a right angle, and applying force steadily. When the pointer points to the torque value, do not apply too much force, otherwise a deviation value may occur. After the measurement is completed, rotate the knob to return the pointer to the zero position for the next application. As a measuring tool, it is necessary to pay attention to protecting the electric torsion wrench. Throwing, shaking, and striking are prohibited.