扭剪型高强螺栓(高强螺栓的分类知识)

Torsional shear type high strength bolt (classification knowledge of high strength bolt)

高强度螺栓的形状和连接结构与普通螺栓基本相同。它们之间高强度螺栓连接的工作原理是有意对螺栓施加较大的预拉力,使被连接件的接触面之间产生挤压力。所以垂直于螺钉方向有很大的摩擦力,连接剪切力就是靠这个摩擦力传递的。高强度螺栓的预紧是通过拧紧螺母来实现的。普通高强度螺栓一般采用扭矩法和角度法。对于剪切型高强度螺栓,通过扭转螺栓尾部来控制预紧力。

The shape and connection structure of high-strength bolts are basically the same as those of ordinary bolts. The working principle of the high-strength bolt connection between them is to deliberately exert a large pre tension on the bolt, so as to generate extrusion force between the contact surfaces of the connected parts. Therefore, there is a great friction force perpendicular to the screw direction, and the connection shear force is transmitted by this friction force. The pre tightening of high-strength bolts is achieved by tightening the nuts. Torque method and angle method are generally used for ordinary high-strength bolts. For shear type high-strength bolts, the pretightening force is controlled by twisting the bolt tail.

高强度螺栓采用10.9S或8.8S级合金结构钢经热处理制成,应钻高强度螺栓孔。摩擦连接高强度螺栓孔径比螺栓的公称直径D为1.5 ~ 2.0mm;承压连接的高强度螺栓孔径比螺栓的公称直径d大1.0 ~ 1.5 mm。

High strength bolts are made of 10.9s or 8.8s grade high-quality alloy structural steel after heat treatment, and high-strength bolt holes shall be drilled. The nominal diameter D of friction connection high-strength bolt hole diameter ratio bolt is 1.5 ~ 2.0mm; The hole diameter of high-strength bolt for pressure bearing connection is 1.0 ~ 1.5 mm larger than the nominal diameter D of the bolt.

按受力状态可分为摩擦型和压力型。

According to the stress state, it can be divided into friction type and pressure type.

其实在设计和计算方法上是有区别的。摩擦型高强度螺栓以板间滑移作为承载能力的极限状态。I型高强螺栓以板间滑移为正常极限状态,以连接失效为承载力极限状态。摩擦型高强度螺栓不能充分发挥螺栓的潜力。在实际应用中,摩擦型高强度螺栓应用于非常重要的结构或承受动荷载的结构,特别是当荷载引起反向应力时。此时,未开发的锚杆潜力可作为储备。此外,应使用承压高强度螺栓,以降低成本。

In fact, there are differences in design and calculation methods. Friction type high strength bolts take slip between plates as the limit state of bearing capacity. The normal limit state of type I high-strength bolts is the slip between plates, and the bearing capacity limit state is the failure of connections. Friction type high strength bolts can not give full play to the potential of bolts. In practical application, friction type high-strength bolts are used in very important structures or structures bearing dynamic loads, especially when the load causes reverse stress. At this time, the untapped anchor potential can be used as a safety reserve. In addition, pressure bearing high-strength bolts should be used to reduce costs.

按施工工艺分为:扭剪型高强度螺栓和大六角高强度螺栓。

According to the construction process, it is divided into torsion shear high-strength bolt and large hexagon high-strength bolt.

六角高强度螺栓属于普通螺钉的高强度等级,而扭剪型高强度螺栓是六角高强度螺栓的改进型,为了更好的施工。

Hexagon high-strength bolt belongs to the high-strength grade of ordinary screw, while torsion shear high-strength bolt is an improved type of hexagon high-strength bolt for better construction.

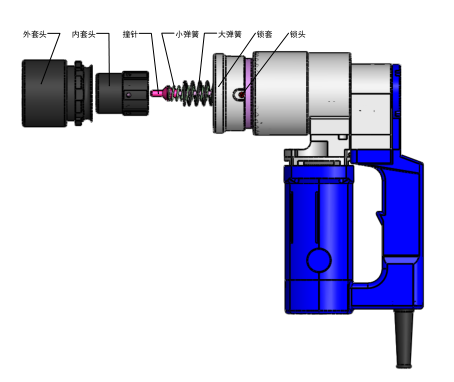

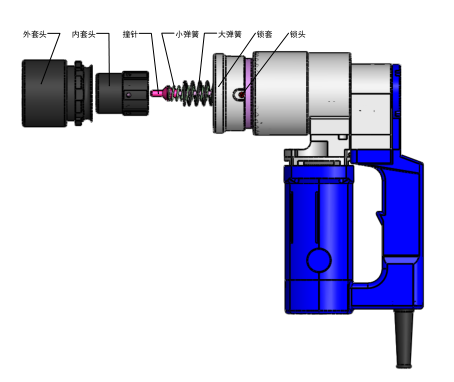

高强度螺栓的施工必须先拧后拧,高强度螺栓初拧应使用冲击式电动扳手或扭矩可调式电动扳手;但对高强度螺栓的更终拧紧有严格的要求。扭剪型高强度螺栓的终拧必须使用扭剪型电动扳手,扭矩型高强度螺栓的终拧必须使用扭矩型电动扳手。

High strength bolts must be screwed first and then screwed. Impact electric wrench or torque adjustable electric wrench shall be used for initial tightening of high strength bolts; However, there are strict requirements for the final tightening of high-strength bolts. The final tightening of torsional shear type high-strength bolts must use torsional shear type electric wrench, and the final tightening of torque type high-strength bolts must use torque type electric wrench.

六角螺栓由一个螺栓、一个螺母和两个垫圈组成。剪切型高强度螺栓由螺栓、螺母和垫圈组成。

The hexagon bolt consists of a bolt, a nut and two washers. The shear type high strength bolt is composed of bolt, nut and washer.

以上就是为大家介绍的有关

扭剪型电动扳手的详细的介绍,希望对您有所帮助.如果您有什么疑问的话,欢迎联系我们.我们将以的态度,为您提供服务.

The above is a detailed introduction to the torsional shear electric wrench. I hope it will help you If you have any questions, please contact us We will provide you with professional service