1、接通电源前应先查看电源电压是否与本国产品铭牌相符,是否有接地装置。当电源电压超出+10%时应采取稳压措施,否则会影响控制精度。接地不良易造成事故。

1. Before connecting to the power supply, it is necessary to check whether the power supply voltage matches the nameplate of the domestic product and whether there is a grounding device. When the power supply voltage exceeds+10%, voltage stabilization measures should be taken, otherwise it will affect the control accuracy. Poor grounding can easily cause accidents.

2、工具使用的环境温度为-10℃-40℃,过高过低会影响控制精度。

2. The ambient temperature for tool use is -10 ℃ -40 ℃, which can affect control accuracy if it is too high or too low.

3、被拧螺栓的初始扭矩不得大于工具的额定扭矩的70%。螺栓达到额定扭矩后不得重拧。

3. The initial torque of the tightened bolt shall not exceed 70% of the rated torque of the tool. Do not retighten the bolt after reaching the rated torque.

4、工具用于拆卸螺栓时,其扭矩不得大于额定扭矩值。一般情况下,不是本扳手拧紧的或锈蚀严重的螺栓,不宜用本扳手拆卸,以免造成工具损坏。

4. When tools are used to disassemble bolts, their torque should not exceed the rated torque value. In general, bolts that are not tightened or severely rusted with this wrench should not be disassembled with this wrench to avoid tool damage.

5、变换旋转方向时,必须待电机停止转动后进行,严禁在运转中拨动正反开关。

5. When changing the direction of rotation, it is necessary to wait for the motor to stop rotating, and it is strictly prohibited to move the forward and backward switches during operation.

6、当扳手自动停止后即可松开开关(如果不断开开关,过5秒钟扳手就会自行启动)待4-5秒后再进行开动扳手,否则扳手不能启动。

6. After the wrench automatically stops, you can release the switch (if you keep opening the switch, the wrench will start itself after 5 seconds). Wait for 4-5 seconds before starting the wrench, otherwise the wrench cannot start.

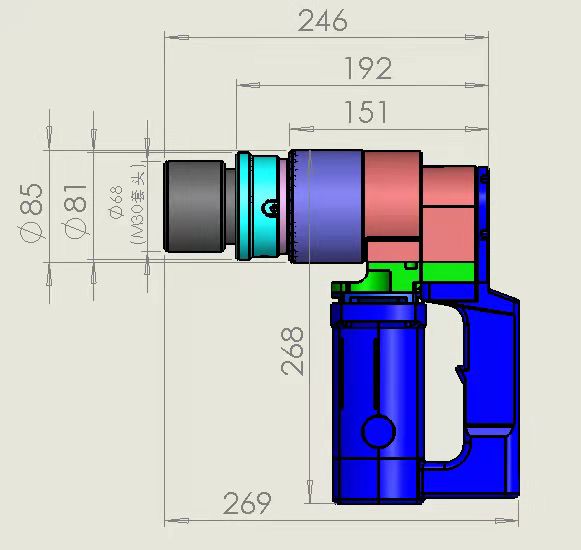

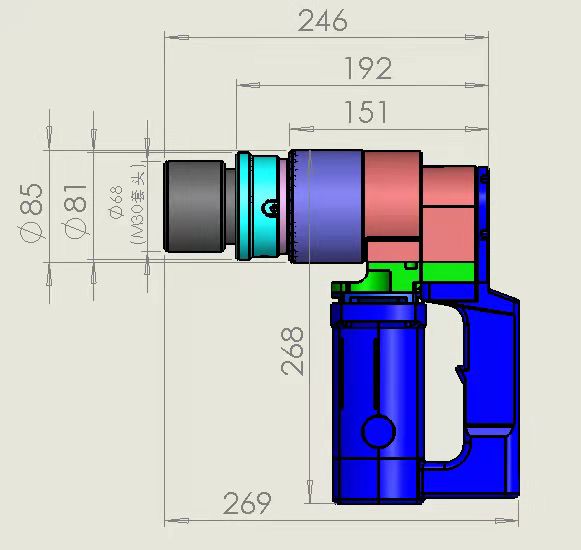

本系列电动力矩扳手是装配螺纹件及螺栓的机械化施工工具,具有自动控制扭矩功能。应用于栓焊结构桥梁的架设,厂房、塔架及化工、冶、发电设备的安装。大型机械、起重设备和车辆装配作业,以及对螺纹紧固件的扭矩及轴向拉力有严格要求的场合。

This series of electric torque wrenches is a mechanized construction tool for assembling threaded parts and bolts, with automatic torque control function. Applied to the installation of bolted and welded structural bridges, as well as the installation of factories, towers, and chemical, metallurgical, and power generation equipment. Large machinery, lifting equipment, and vehicle assembly operations, as well as occasions with strict requirements for torque and axial tension of threaded fasteners.

电动扭矩扳手螺栓的拧紧操作

Tightening operation of electric torque wrench bolts

1、装上反力支架,并紧固螺钉。开动主机,使方头销孔与反力支架孔相对应,然后装入扳手套筒,插上销钉,并用橡胶圈固定。

1. Install the reaction bracket and tighten the screws. Start the main engine so that the square head pin hole corresponds to the reaction support hole, then install the wrench socket, insert the pin, and fix it with a rubber ring.

2、将控制仪的扭矩旋钮调到所需扭矩值,将主机正反开关拨到正转位置,把扳手套筒套在螺纹连接件的六方上。

2. Adjust the torque knob of the control instrument to the desired torque value, turn the forward and reverse switches of the main engine to the forward rotation position, and place the wrench socket on the hexagonal side of the threaded connection.

3、按下电源开关,扳手启动。当反力支架力臂靠牢支架时(支点可以是邻近的一只螺栓或其他可作支点的位置)螺栓开始拧紧。当螺栓扭矩达到预定扭矩时,扳手自动停止,紧固完成,松开电源开关,进行下一只螺栓的拧紧工作。

3. Press the power switch and start the wrench. When the force arm of the reaction bracket is firmly against the bracket (the fulcrum can be an adjacent bolt or other position that can serve as a fulcrum), the bolt begins to tighten. When the bolt torque reaches the predetermined torque, the wrench automatically stops, the tightening is completed, the power switch is released, and the next bolt tightening work is carried out.

4、扳手自动停止后,靠反力支架的弹性形变力,使支架力臂自动脱离支点,取下扳手。如力臂不能脱离支点时,可拨动正反开关,点动电源开关扳手即可取下。

4. After the wrench automatically stops, relying on the elastic deformation force of the counter force bracket, the force arm of the bracket automatically disengages from the fulcrum and the wrench is removed. If the lever arm cannot detach from the fulcrum, the forward and reverse switches can be toggled, and the power switch wrench can be removed by jogging.

本文由

扭剪电动扳手友情奉献.更多有关的知识点击:

我们将用真诚的态度.为您提供为的服务.更多有关的知识我们将会陆续向大家奉献.敬请期待.

This article is a friendly contribution from the torsion shear electric wrench. For more relevant knowledge, click on: We will provide you with comprehensive services with a sincere attitude. We will gradually contribute more relevant knowledge to everyone. Stay tuned